Visitors to the AMAB facility in Asse are greeted by the sight of chocolate, beer and other tasty treats. These are just some of the products that AMAB packs for redistribution under its contract packing agreements with customers such as Colruyt. Co-packing has been one of the mainstays of AMAB's business since the start – but now things are gradually changing.

AMAB is a social enterprise for customised work (formerly known as a sheltered workshop) which has over 800 employees in three locations around Brussels. Approximately 700 of these employees have a physical or mental disability that makes it difficult for them to find a job. Olivier Bernard, Director Finance & & IT, explains how their organisation works: 'Social enterprises like ours aim to provide customised jobs to people who are not able to work in a normal work environment. The goal is to give their life purpose and help them play an active role in the working world. The first thing we do before accepting a job from a customer is to carry out a feasibility study. Our aim is to develop a working environment based on the three pillars of sustainability (People, Planet, and Profit) – an environment that inspires personal growth among those who cannot participate in the conventional world of work. We combine these social integration objectives with cost-efficient practices that make good economic sense.'

FROM PACKING TO WASHING

AMAB has been offering contract packaging services for a number of years – an activity that is well-suited to people with disabilities. 'But it doesn't really tick all the boxes in the Planet category of the 3P philosophy. So that's why we decided to introduce a new activity as a third key line of business alongside our co-packing and electronics assembly services. It stemmed from an idea we had in 2019 to start washing reusable cups, and it is very much based on the principles of the circular economy. We got in touch with Festicup, a company that sells and rents reusable cups. Its services are the perfect match to what AMAB offers, so together we can provide an all-round recycling solution that meets the needs of end customers who value sustainability. Legislators gave our project a real boost in 2020 when they made it obligatory for municipalities and event organisers in Flanders to use reusable cups. If an organiser opts to use disposable materials instead, they are required to recycle 95 percent of those materials. That's an almost impossible challenge, so reusable cups will increasingly become the norm,' says Olivier.

SUSTAINABLE PARTNERSHIP

AMAB's first task was to find a suitable machine for washing the cups, says Olivier: 'We did a lot of research into what machines were available on the market and what requirements the machine would have to meet, particularly in regard to our employees' disabilities. MEIKO really stood out during that research phase. David Jacobs from MEIKO Belgium was tremendously responsive to our needs right from the start, both in terms of our mindset and our philosophy. We set MEIKO the challenge of creating a machine that had never really been developed before. They immediately recognised the potential, and they were really enthusiastic about getting involved in a social project. They did everything they could to cater to our needs, and the machine they came up with is perfectly tailored to the cups and to the employees who work with the machine.'

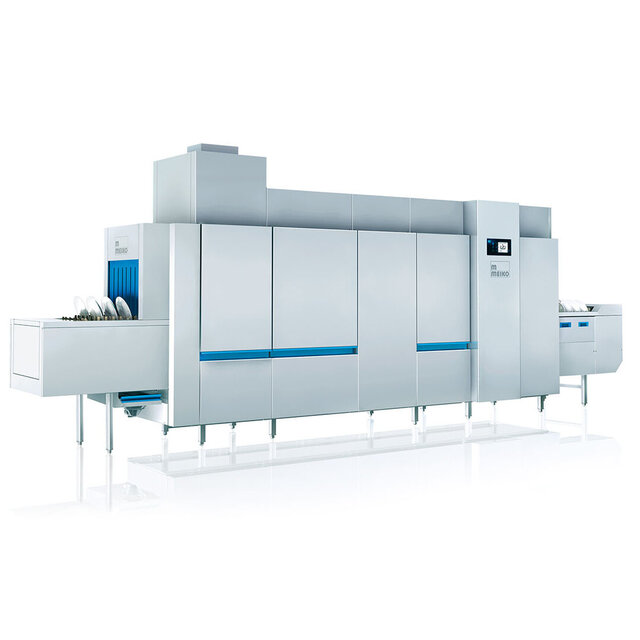

The machine AMAB uses is a M-iQ flight type dishwasher with a length of 14 metres. It can wash and dry 8, 000 cups an hour. The machine includes a built-in cooling unit that is designed to ensure optimum drying. By cooling down the cups, it prevents the formation of condensation and mould. AMAB also chose to have the conveyor belt equipped with "fingers", says Olivier: *The idea was to simplify things so that employees with disabilities could easily manage the work. If we had chosen racks, which each hold 35 cups, that would have required people to count the cups each time. That isn't as easy as it seems, and for some people with a disability it can be really tough. MEIKO understood that immediately and offered us an alternative that wasn't available from its competitors. The idea was that one finger would correspond to one cup, which made it into a simple and repetitive task. The same principle was applied to drying.

Plastic is not an easy material to dry, and the technology we needed was still in an embryonic stage. But by speeding up the development process, MEIKO was soon able to prove beyond any doubt that it could get the plastic completely dry before it came out of the machine. And that ticked off the last point on our checklist for working with MEIKO. We consider partnerships to be an essential part of our business. We're looking for a long-term business relationship, so reliability, openness and transparency are much more important to us than just getting the best price. This applies to all our suppliers. MEIKO not only proved to be responsive, accessible and professional but, even more importantly, they were clearly determined to understand our needs – and that's when we knew we had found the right partner!'

WASH-IT FOR THE WHOLE FLANDERS REGION

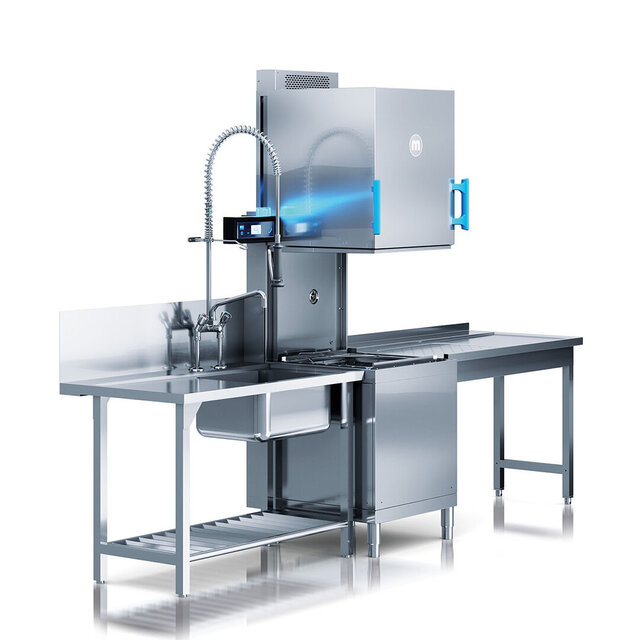

Just as AMAB and Festicup were embarking on their project to wash reusable cups, the year 2019 also saw AMAB sign up for the Wash-it initiative, which aims to achieve similar goals for the whole of Flanders. A consortium of companies was formed to provide a sustainable solution for the entire region, with each province getting its own washing centre. 'A single rock festival like Rock Werchter can get up to 80,000 visitors a day. If each of them has an average of five drinks, you're looking at 400,000 cups a day. These have to be washed within a specified time to guarantee quality. The shorter the chain, the less wasteful and more sustainable the process.' A total of five sheltered workshops and social enterprises are now working with Wash-it: AMAB, Sobo, Ateljee, ACG and Bewel. Each workshop houses a M-iQ dishwasher for washing the cups and a M-iClean H hood type dishwashing machine for washing the crates.