HYGIENE IN AN INFINITE LOOP

Hygiene can only be complete with the right process

The safety of our technology is one thing, but everything else also has to be right in order for hygiene not to suffer. We look at every detail, we know the critical points and we think processes through all the way to completion.

The fundamentals of a cleaning process

Whether glasses, BA masks or bedpans: all washware goes through a process from the point at which it is taken out of use to when it is made available for use again.

One basic principle is always the same, aiming to avoid contamination and break chains of infection:

keeping clean away from unclean at all times.

At the planning stage, this means:

- Unclean or black area =

collection point for dirty washware - Clean or white area =

collection point for reprocessed washware - Spatial separation between areas before and after cleaning, ideally of a structural nature in the form of a partition wall

- Transportation routes for clean and unclean washware must not intersect

In application, this means:

- Clean hand = for the cleaned washware and the surrounding environment (e.g. door handles), i.e.

- No contact with soiled washware

- Gloves optional

- Unclean hand = for soiled washware, i.e.

- No contact with reprocessed washware and the surrounding environment

- Gloves important

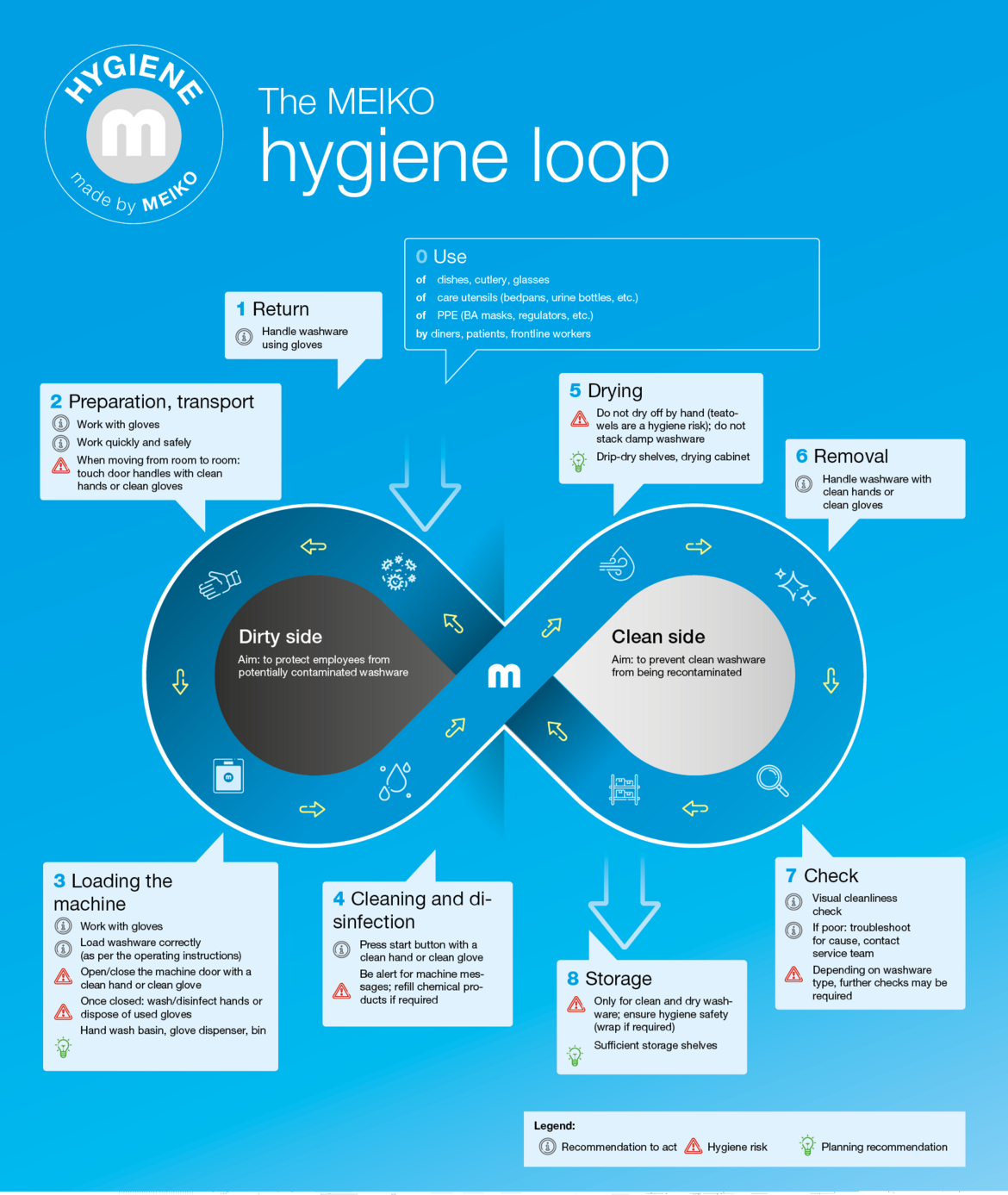

THE MEIKO HYGIENE LOOP

The MEIKO hygiene loop plots out a possible workflow for a cleaning process, regardless of the object to be cleaned but inclusive of recommended actions and structural recommendations.

There is no limit to the number of times the process it illustrates can be repeated. However, the result is always the same:

hygienically safe washware that can be reused without hesitation.