SUSTAINABILITY

‘Human health is intrinsically linked to hygiene – and to the health of our planet.’

We have been running on the power of innovation since 1927! And it goes even further than our products. We are pioneers within our sector, delivering comprehensive, efficient, economical solutions with huge customer benefits. We are excited to face the next challenge: how can we solve the problem even better? We use our gifts of exploration and innovation to develop the perfect solution to fulfil our customers' every expectation.

Life, nature, planet Earth: these are gifts to us and we must treasure them. That is why, at MEIKO, we do not think in business quarters. We think in generations. We always have an eye on the bigger picture and we're setting up all of our departments for greater sustainability. This is how we fulfil our environmental, social and economic responsibilities. Our products are highly resource efficient and our food waste treatment systems can help generate energy.

We nurture a culture of trust and are able to rely on one another. Our employees expect this and so do our customers, but also everyone with whom we have a business relationship. We journey with them and we are always there when we are needed, often over the course of decades. This helps us to achieve great things and reach our own goals.

Our world is changing apace. We are setting up new structures to respond to ever-more dynamic market conditions. MEIKO's history spans almost 100 years and, throughout that time, we have proven again and again that we know how to adapt to change quickly. And we have never stopped learning – that is key. We consistently take on board ideas from our market organisations and employees.

We are passionate about anything to do with quality. Our customers and partners expect excellent results and sustainable solutions to exceed their every request – and that applies to employee expertise, too. The MEIKO Academy exists to train our employees and meet this need.

MEIKO is a company that brings together a rich diversity of personalities, temperaments and cultures. That is a positive experience and we commit to treating one another fairly and respectfully, valuing people and acting in harmony with nature. This underpins everything.

SUSTAINABILITY

Sustainability – environment, social, and business – is a feature of our management system. Eco-friendliness, energy management, and occupational health and safety are key components of this and are all regularly reviewed by independent institutions.

Our strategy design aims to continually move MEIKO's sustainable corporate governance forward and further reduce our ecological footprint. To this end, our organisational and staffing strategies are positioned for the future, including all the resources they need.

Our sustainability statement below goes into more depth.

DOWNLOADS

ENVIRONMENT

Caring for the environment is a role of business and it is part of our responsibility to society. MEIKO products are therefore designed to fulfil this goal, among others. Machine warewashing, cleaning, and disinfection, has always been a sustainable approach because it saves time compared to manual processes, as well as increasing product lifespan, avoiding tons of single use-product waste, and it can even conserve resources like water, energy, and chemicals.

Our sustainability management strategy has been ISO 14001 certified since 2016. Its impact is felt to the full in the production, service, and disposal phases. In addition, we are continuing to reduce our environmental impact and expand our sustainability management strategy to achieve all of our environmental goals in transparent and measurable ways.

Our main production site is in Offenburg. It runs based on a large vertical range of manufacture, producing as much as possible in house. This means that we can actively shape individual process steps, and therefore actively improve our energy, material, and resource efficiency going forward.

Further production sites are located in the USA and China to serve the markets in those regions.

CLIMATE CHANGE

Slowing climate change will require willingness to undergo a transformation and we recognise that. We are therefore adapting our climate management strategy to the coming challenges with the aim of continuing to reduce our greenhouse gas emissions.

ENERGY WITH ZERO CO2 EMISSIONS

We have been running on 100% green electricity since 2021. Since electricity accounts for more than 50% of our energy consumption, this saves 4,904 MWh, or the equivalent of 2,128 tonnes of CO2. As a comparison: the average electricity mix in Germany releases 2 tonnes of CO2 per year through domestic use. Our carbon saving from using climate-neutral electricity is therefore the equivalent of the usage of 1,008 two-person households in 95 m2 homes.

Plus, we generate 18% of the energy we need ourselves with our photovoltaic installation.

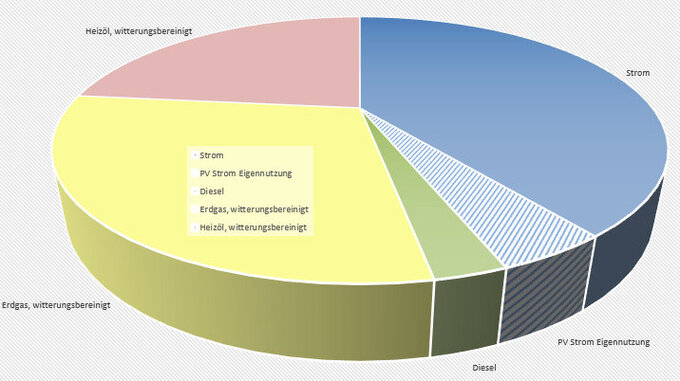

ENERGY DISTRIBUTION 2022

| Electricity | 4,401,418 kWh/a |

| PV electricity, in-house use | 502,539 kWh/a |

| Diesel | 324,292 kWh/a |

| Natural gas, weather dependent | 3,264,762 kWh/a |

| Fuel oil, weather dependent | 2,583,974 kWh/a |

MEIKO buildings are optimised for low energy consumption. Our new building in Offenburg is equipped with a groundwater heat pump that we run using energy from renewable sources. The lighting in the company has been converted to LED.

MEIKO's energy management strategy is comprehensive and certified to ISO 50001 standard. This drastically reduces the consumption of energy for heating through technical and organisation action. Further steps to maximise energy efficiency have also been taken in production, e.g. the use of laser welding.

RESOURCE USE & THE CIRCULAR ECONOMY

Products – the large lever

The lion's share of our corporate carbon footprint comes from the operational use of our machines. That means: the large lever in resource conservation and the circular economy is our customers' use of our products.

Optimising resource use in our machines (energy, water, chemicals) has always been a strategic focus for our design team and lab work. Consumption levels are defined in the product requirements document and are continually reduced. Regular lab testing on material efficiency and durability are routine, as are extending the life of our products and using sustainable materials.

That is how we achieved a 38% energy saving in our UPster K M2 machine using heat recovery. Our M-iClean H uses heat recovery to save 18% in energy costs and provides an improved indoor climate by reducing steam emissions by around 80% (both figures as compared to the previous model).

CONTINUING TO DEVELOP OUR PRODUCTS IN THE CONTEXT OF SUSTAINABILITY

MEIKO products for washing reusable dishware for off-trade sales are one way to create sustainable processes within our customers' day-to-day operations. After all, we are helping them to switch from disposable to reusable plastic dishware for takeaway coffees, for drinks at festivals, and at football matches.

Drying plastic cups presents unusual challenges for warewashing technology. The same is true for washing reusable glass bottles, an ever more popular item in the food service sector.

In this respect, MEIKO products are helping to avoid large quantities of waste, conserve resources, reduce greenhouse gas emissions, and make way for a sustainable circular economy based on reusable dishware and deposit systems. Plus, we are strengthening this transformation by working with customers, event organisers, and associations where we are a member, such as United Against Waste.

PRODUCTS THAT PROTECT THE HEALTH

of their users

We clean respiratory or personal protective equipment (PPE) to protect the user from disease, i.e. to safeguard their health. With our cleaning and disinfection technology for emergency services, along with our expertise in equipping SCBA workshops, we deliver on occupational health and safety for both wearers of respiratory protective equipment and SCBA technicians. Our machines decontaminate equipment that has been exposed to toxic substances or pathogenic microorganisms, providing a huge boost to occupational safety.

MEIKO machines clean stainless steel care utensils like bedpans in hospital and care home utility rooms. This provides a long-lasting alternative to single-use care utensils made from plastic, paper, or card, some of which are disposed of in the waste water system. Our washer-disinfectors are even proven to have a lifespan three times longer than a refuse grinder connected to the waste water system.

Our own waste management system is externally assessed as per ISO 14001. One strategy we employ to reduce our transport packaging waste is the use of returnable packaging made from FSC-certified wood. All unavoidable production waste goes to our regional refuse disposal provider and the majority is reintroduced into the material cycle.

THE REPARABILITY AND RECYCLABILITY

of our products

The reparability and recyclability of all MEIKO products is a key part of our sustainability programme. Our aim is to use regular lab testing to continually improve on material efficiency and durability. We foster sustainable collaboration and a growing depth of interconnection with our partners.

As a foundation, our machines are made resource-efficiently using stainless steel, which is inherently recyclable. Our technical service employees are also involved in maximising the length of the product life cycle.

We have service centres all over the world and if our customers experience a break down, we make sure that everything is back up and running again as soon as possible with the support of our many authorised service partners and service technicians. The service department also reconditions old machines so that they can be used as substitutes in an emergency.

RESOURCE CONSUMPTION

in infrastructure and production technology

SOCIAL

MEIKO and the public's social & environmental concerns

END USERS

Safeguarding people from disease is one of our prime directives. The consequences of the COVID-19 pandemic thrust the need for hygiene into the spotlight, and made it a huge global priority. MEIKO warewashing, cleaning and disinfection technology has been boosting health around the world for almost 100 years, helping to keep people safe from infection. That applies to patients, healthcare workers, diners, and employees of fire and rescue services who are exposed to carcinogenic substances. We clean using water, chemicals, and heat. This is the only way to ensure the safest results. While maintaining the required hygiene standards, MEIKO products are also designed to be as sustainable as possible.

As part of our compliance management system, we facilitate active risk monitoring to detect potential risks to end users from our products. Plus, we deliver excellent safety and ergonomics to users of our technology. To do so, we plan the area surrounding our machines based on work processes, functionality and ergonomics.

As a company working to design technology that boosts safety, we believe it is our responsibility to inform machine end users of potential risks, and to minimise these risks. That is why we included the following guidelines in our code of conduct: Visit code of conduct

OUR OWN STAFF

MEIKO has been run as a foundation for almost 100 years, with job security within the company among the foundation's aims. This why approx. 1,300 or our 2,800 employees work at our main site in Offenburg – some of them are even the third generation of the same families working for us.

Good pay, company pension scheme, fair treatment, a large cohort of trainees, and much more are all signs of how the company is oriented towards its employees' needs. We even have holiday homes for our employees to use for their family holidays.

MEIKO also subsidises public transport for employees and we encourage staff to cycle to work with our bicycle leasing scheme.

People are our most precious resource. Occupational health and safety is therefore a particularly high priority at MEIKO.

Occupational health and safety management comprises occupational health and safety, safeguarding health, and fire prevention. It is how we make the workplace safe and safeguard employees from work-related health problems. The MEIKO occupational health and safety management system fulfils all relevant requirements found in law and technical standards or stipulated by the employers' liability insurance associations and is certified in accordance with the international standard for occupational health and safety ISO 45001.

We also help our employees to progress their personal lives, for example by helping them bring together work and family life and providing further training within the company through the MEIKO Academy. The Academy offers a wide range of online and in-person training courses. Of course, we also support further training opportunities offered by third parties. We care about the details: we also subsidise the MEIKO canteen, where vegetarian and vegan options are available daily.

SUPPLY CHAINS AND HUMAN RIGHTS

Even a company owned by a foundation like MEIKO needs financial success to build a future. For us, that is inextricably linked to our behaving responsibly towards the environment, in our relationships with people, and within society. And that goes for our entire supply chain.

We therefore expect our employees and our suppliers and partners worldwide to follow the same guidelines that we do, e.g. the ILO's (International Labour Organisation) Declaration of Principles.

- we support and respect the protection of internationally proclaimed human rights.

- we make sure that we are not complicit in human rights abuses.

- we recognise the fundamental requirement for workers' rights.

- we strive to increase awareness and minimise or eliminate negative effects on our employees or people outside of the company.

BLACK FOREST

SUSTAINABILITY FORUM

At Offenburg University of Applied Science's 5th Black Forest Sustainability Forum, MEIKO shared expertise as a forum member. One of the UN's 17 sustainability goals was on the agenda: discussing action and solutions to provide water access for everyone, sustainably manage water resources, and deliver sanitation to every person. MEIKO's water-saving technology serves as a model for resource efficiency in cleaning and disinfection.

WE HAVE ALSO ESTABLISHED THE FOLLOWING BODIES:

- Our company is by the book and that is important to us. That is why our compliance management strategy impacts all departments and our Code of Conduct mandatorily applies to everyone.

- Our risk management strategy takes into account stakeholders and opportunity-risk management.

- We also have a long-term complaint management strategy and use the BKMS whistleblower system.

- The tagline to the company name MEIKO is, ‘the clean solution’. We chose it with reference to our products, but we also always want it to describe our actions: clean, clear, and transparent. That goes for all employees and directors.

We are currently in the process of developing a CSRD-compliant sustainability management system that will be the basis for how we act in the future. Our strategy incorporates several important steps to ensure that we are fulfilling our environmental and social responsibilities.

The first step is to conduct a double materiality assessment. This will help us to identify the most significant sustainability issues for the business and our stakeholders.

A further central pillar is to further strategise how to shrink our ecological footprint. We will precisely measure and analyse our CO2 emissions and other environmental impacts. We will then use this data to design targeted strategies to reduce our ecological footprint.

Based on the results of the materiality assessment and the climate impact, we will expand our sustainability strategy. We will define clear aims and actions that we will monitor using KPIs. This strategy is being developed in close collaboration with all departments involved.

Our extended sustainability aims and actions will be integrated into day-to-day operations to ensure that sustainable behaviour remains a key component of our business practices going forward.

From 2026, we will regularly publish CSRD-compliant reports to document our progress in a transparent way. We will also adapt our communication to provide extensive information about our actions to our customers and stakeholders.

These actions set the directions for a sustainable future and ensure that MEIKO will continue to act responsibly with a focus on the future.